Our Dorner Conveyor experts will help you every step of the way to help you build a reliable system with efficient throughput. Our goal is to save you time and money. Click the button to get started.

Our Dorner Conveyor experts will help you every step of the way to help you build a reliable system with efficient throughput. Our goal is to save you time and money. Click the button to get started.

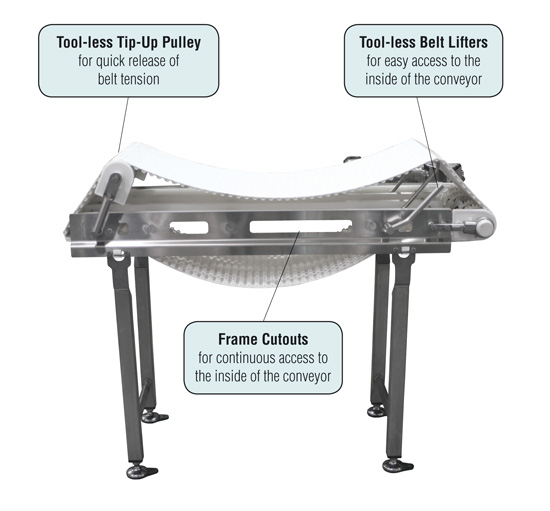

Dorner’s 1100 Series miniature conveyor has the lowest profile in North America. The conveyor is designed for small or lightweight part handling and it can easily fit inside machinery and equipment. It is ideal for pharmaceutical, medical and life science applications.

© 2015 Stamp Tech, Inc. Designed by Prontologic.com