Dorner ConveyorS

Conveyor Products & Systems

Conveyors play a pivotal role in the manufacturing industry, serving as a fundamental component of the production process. These mechanical systems are designed to efficiently transport materials, goods, or products from one point to another within a facility. Conveyors streamline workflows by automating the movement of items, enhancing overall efficiency and productivity. They are versatile and can be customized to accommodate various shapes, sizes, and weights of materials, making them suitable for a wide range of industries such as automotive, food and beverage, pharmaceuticals, and more. Conveyors contribute to cost reduction and labor optimization, allowing manufacturers to achieve higher output rates while minimizing manual handling. The implementation of conveyors in manufacturing reflects a commitment to modernization and operational excellence, facilitating the seamless flow of materials through different stages of production.

1X Series

The 1X Series Line is designed for small part handling and transfers where space is a premium.

Type

- Flat Belt

- Clean Room

Applications

- Small or light weight product movement

Medical - Pharmaceutical

- Life sciences

Sizes & Measurements

- Flat Belt End Drive, or Flat Belt Mid Drive

- End Drive – 1″ (25 mm) Diameter Drive Pulley

- Mid Drive – 1.25″ (32 mm) Diameter Center Drive Pulley

- 0.625″ (16 mm) Diameter Idler Pulleys

- 0.31″ (8 mm) Diameter nose bar option for one or both ends

- Belt Widths: 1.75″ (44 mm), 3.75″ (95 mm), 6″ (152 mm), 8″ (203 mm), & 10″ (254 mm)

- Conveyor Lengths: 10.63″ (270 mm) to 72″(1829 mm) in 1/8″ (3 mm) increments

- Loads up to 15 lbs (6.8 kg)

- Belt Speeds up to 80 fpm (21 m/min)

2X Series

The 2X Series Line is engineered for small to medium sized parts, precision applications and flexible layouts.

Type

- Flat Belt

- Cleated Plastic Belt

- Modular Belt

- Timing Belt Conveyors

General Applications

- Small to Medium Part Handling

- Transfers

- Accumulation

- Precision Parts Movement

- Part Incline/Decline Routing (Z Frames)

- Positioning

- Automated and Manual Assembly

3X Series

The 3X Series Line is designed for medium to heavy sized parts, precision applications, bulk handling and flexible layouts.

Type

- Flat Belt

- Cleated Belt

- Modular Plastic Belt

- Precision Move

Loads & Speeds

- Loads up to 1000 lbs (455 kg)

- Belt speeds up to 400 ft/min (122 m/min)

Size & Measurements

- Belt widths: 6″to 48″

- Conveyor lengths: 36″ to 999″

AquaGard / AquaPruf

AquaPruf® / AquaGard® Series Stainless Steel Line is engineered for small to heavy product requiring various levels of sanitary design and flexible layouts.

Type

- AquaPruf® + AquaGard®

- Flat Belt

- Cleated Belt

- Modular Plastic Belt

- Flexible Chain

General Applications

- Packaging

- Bottling

- Dry Food Processing

- Part Handling

- Long Lengths

- Accumulation & Buffering

- Flex Move

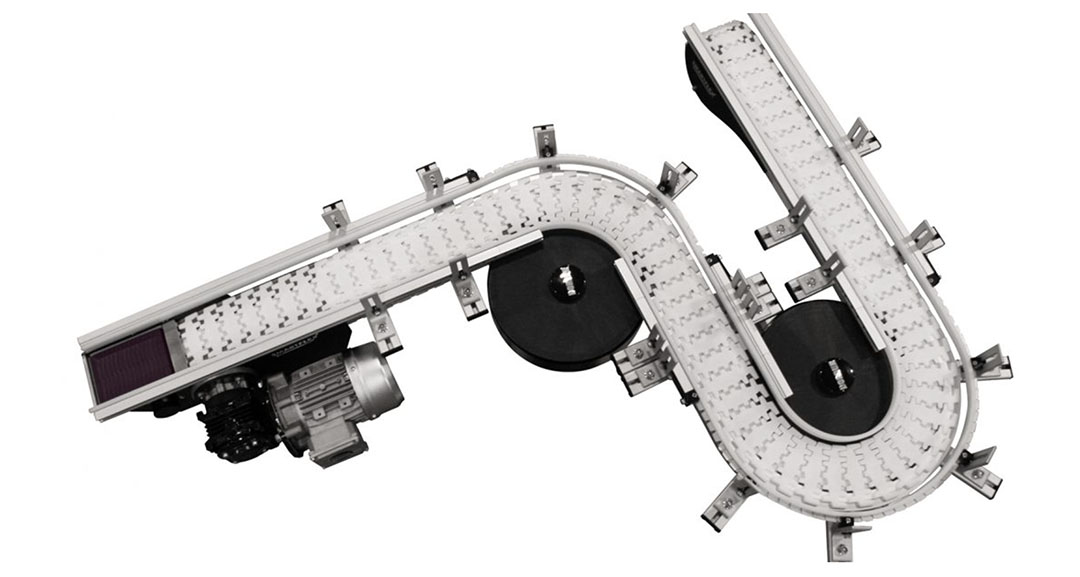

FlexMove

FlexMove Conveyors offer a variety of options with unique features, such as flexible chain with cleats, rollers, friction pads, steel top, anti-static and also fabric belts.

Options

- Available in 45mm, 65mm, 85mm, 105mm, 150mm, 180mm and 260mm widths

- Many varieties of turns, angles, inclines and declines available

FlexMove Series Conveyors are Best For

- Part Handling

- Transfers

- Tight Spaces

- Assembly Automation

- Packaging

- Machine Conveyance

- Elevation Changes

- Accumulation

- Buffering

- Complex Configurations

- Long Lengths

- Curves, Jogs, Incline, Decline