Our Dorner Conveyor experts will help you every step of the way to help you build a reliable system with efficient throughput. Our goal is to save you time and money. Click the button to get started.

Our Dorner Conveyor experts will help you every step of the way to help you build a reliable system with efficient throughput. Our goal is to save you time and money. Click the button to get started.

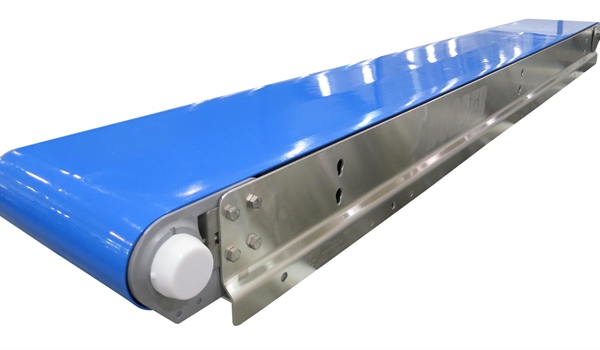

Option accessories for the AquaGard® 7360 include: guides, transfers, drip pans, hoppers, and more.

© 2015 Stamp Tech, Inc. Designed by Prontologic.com