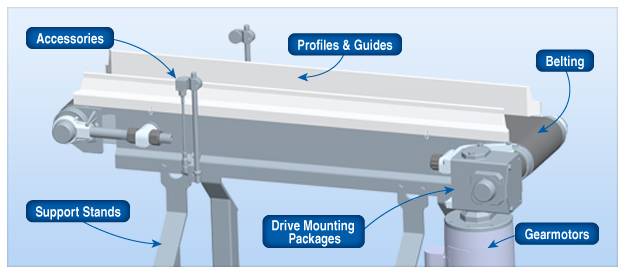

Our Dorner Conveyor experts will help you every step of the way to help you build a reliable system with efficient throughput. Our goal is to save you time and money. Click the button to get started.

Our Dorner Conveyor experts will help you every step of the way to help you build a reliable system with efficient throughput. Our goal is to save you time and money. Click the button to get started.

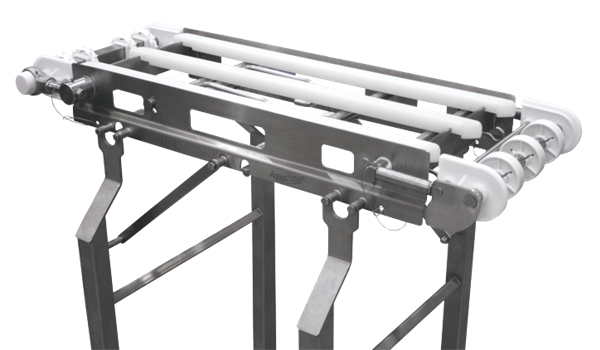

The ULTIMATE Series has been engineered for Fast & Effective Sanitation in the most demanding environments. These include RTE foods, raw protein (meat – poultry – fish), dairy and other environments with high pressure sanitation requirements.

The ULTIMATE Series has been engineered for Fast & Effective Sanitation in the most demanding environments. These include RTE foods, raw protein (meat – poultry – fish), dairy and other environments with high pressure sanitation requirements.

Specifications

Frame is designed with no horizontal surfaces for optimum cleaning. Conveyors over 10′ long consist of multiple sections which are bolted together (can be welded together on site).

Frame is designed with no horizontal surfaces for optimum cleaning. Conveyors over 10′ long consist of multiple sections which are bolted together (can be welded together on site).

© 2015 Stamp Tech, Inc. Designed by Prontologic.com