Machine Safe Guarding

It’s All About Safety

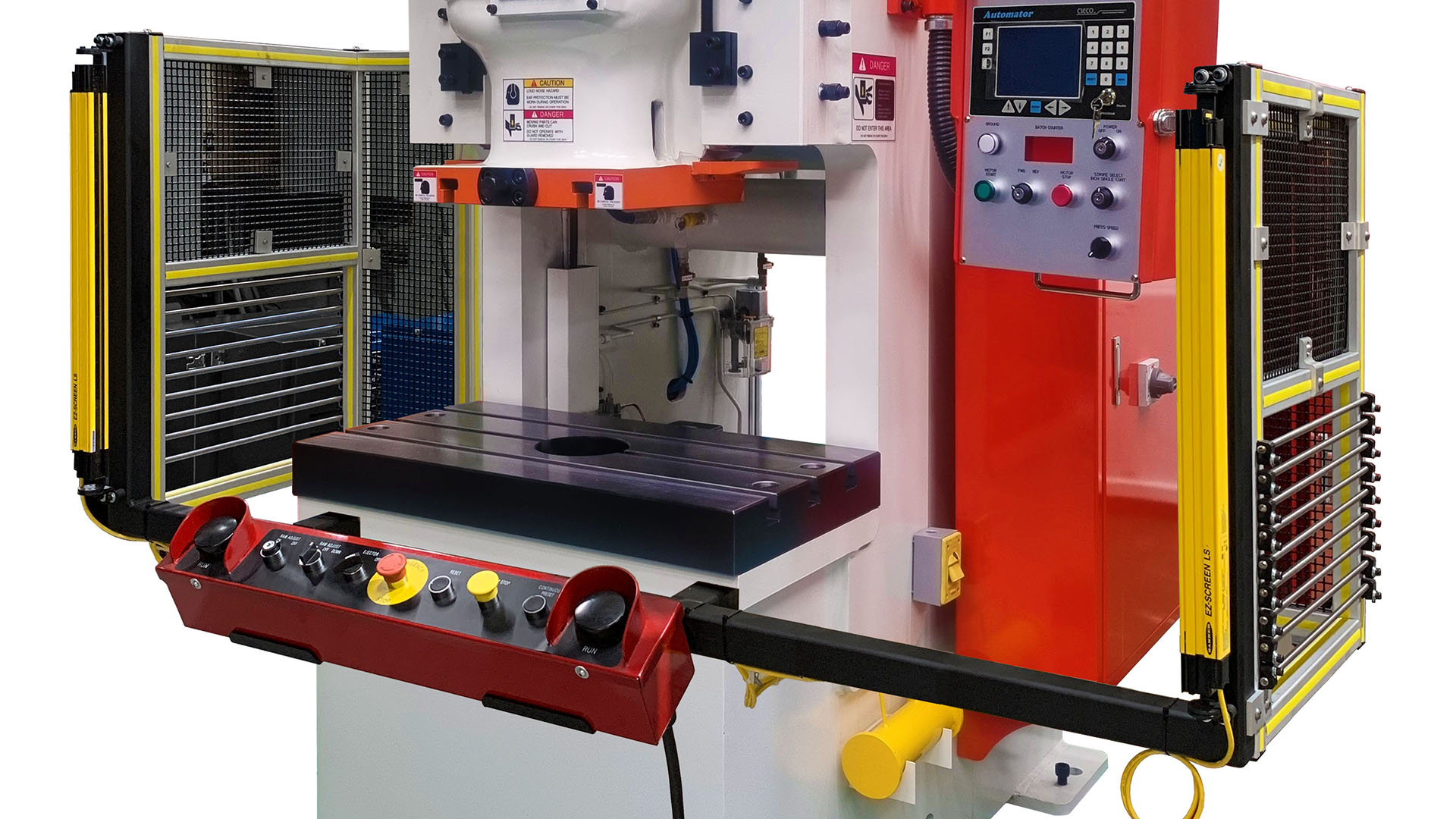

Our factory trained service technicians can manufacture custom safe-guarding in your shop for all types of machines. Some of our machine guard solutions use presence sensing devices, such as light curtains. All of our safe-guarding products are constructed of high-quality materials including extruded aluminum, LEXAN (a bulletproof material) and wire mesh inserts to make all machinery OSHA compliant.

Importance of Machine Safeguarding

The primary objective is to create a secure work environment by employing various safety mechanisms that either physically guard or control access to hazardous machinery components. These safeguards can include barriers, sensors, interlocks, and emergency stop devices. The purpose is not only to mitigate the risk of injuries but also to comply with occupational safety standards and regulations. Machine safeguarding plays a crucial role in preventing accidents caused by inadvertent contact, flying debris, or other potential hazards associated with operating machinery, contributing to the overall well-being of workers and the efficiency of industrial processes.

StampTech Provides Machine Safeguarding for:

Presses

Brakes

Shears

Turning Machines

Conveyors

Automated Machinery

Chip Making Machinery

Professional Staff

StampTech has safeguarded machinery since 1986. Each of our factory-trained service engineers keep current with the latest laws and regulations set by OSHA.

Maximum Value

We’re serious about machine guarding and your satisfaction. After a machine is surveyed — we’ll provide drawings for your approval — before a guard is supplied.

Peace of Mind

No one wants, or can afford, an accident. At StampTech our specialists handle your machine guarding requirements from start to finish. All of our work is documented and recorded and we will conduct yearly inspections on machines for year-to-year comparisons.