Turnkey Systems

Automate Your Products

StampTech is nationally known for its system capabilities. From a simple drawing, StampTech can supply you with a full system. We offer complete design, building and system runoff at our facility. Ship us your existing line, we can refurbish and upgrade it to new and provide operator training on all systems.

We’re Picking Up What You’re Putting Down

Process automation in the metal stamping industry utilizes technologies to optimize and streamline various stages of manufacturing. This not only reduces manual labor but also enhances the overall efficiency of the production line. Another aspect of metal stamping automation is the integration of robotic systems for tasks such as part feeding, positioning, and removal. These robots execute these functions with precision and speed, contributing to improved accuracy in the stamping process. With the implementation of feedback sensors and cameras for real-time quality control adds an extra layer of reliability, ensuring that only high-quality stamped parts make their way through the production process.

Anatomy of Automation

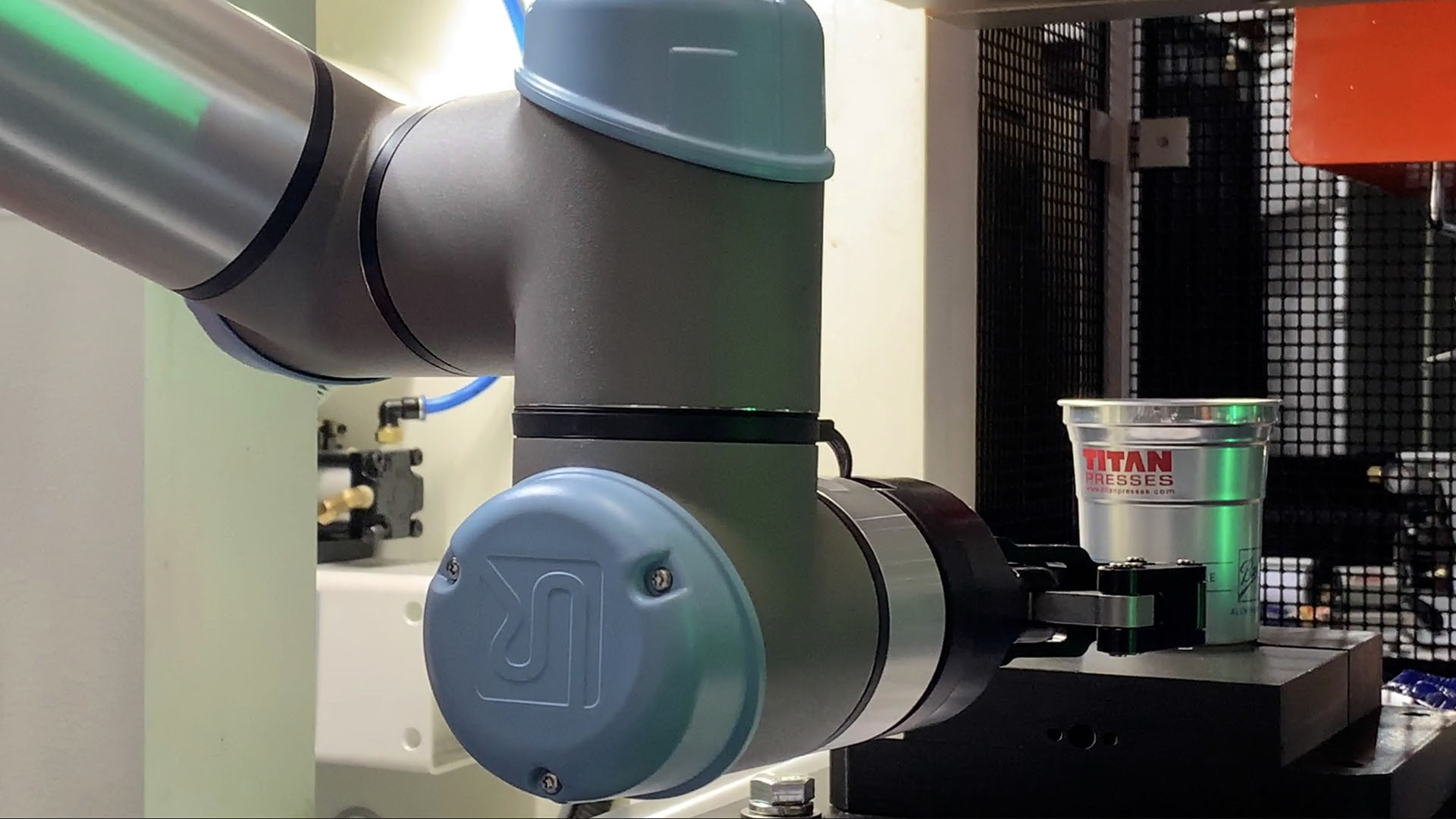

Robots & Controllers

Light Curtains

Programmable Limit Switches

Pick & Place Systems

Die Protection

Swift Trip Mode

Tonnage Monitor

Decoilers

Servo Feeds

Conveyors

Less Machine Downtime

Investing in your production line will help in many ways. Being able to repeat tasks quickly and precisely is the name of the game. Time is money and if you are spending most of it making adjustments or cobbling procedures together you will benefit from a fully automated metal stamping press designed and built to your specifications. Here are some benefits of automated systems in the manufacturing industry.