SPECIFICATIONS:

Noise control systems for manufacturing parts using mechanical presses are designed to reduce the high levels of noise generated during operations like stamping, punching, or forming. These presses create impulsive and continuous noise that can be hazardous to workers and violate occupational safety regulations. Here’s a breakdown of common noise control methods used in these settings:

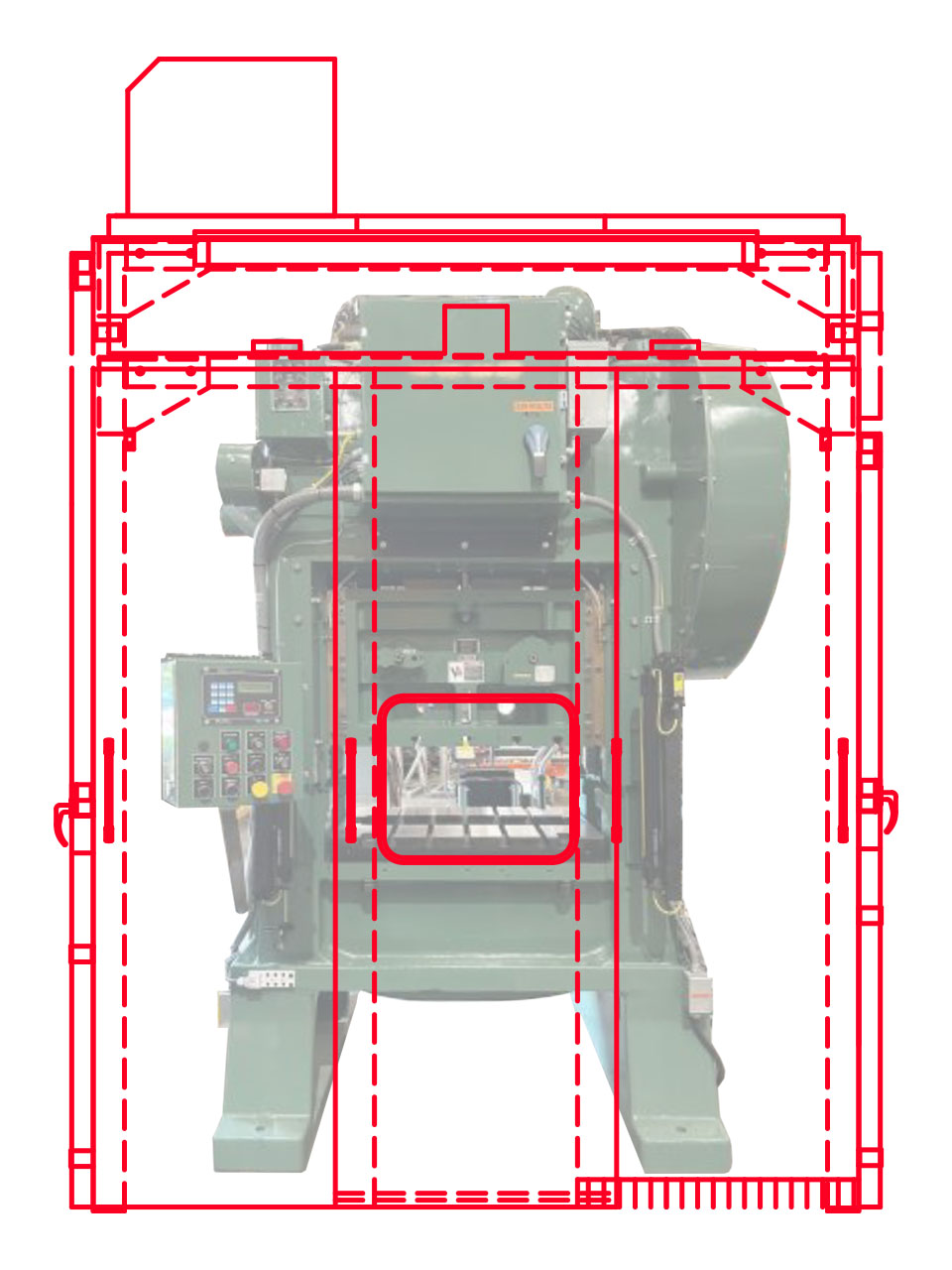

Overall Dimensions

-

- 98″L x 63″W x 124″H

- PDF Download Specifications

IDEAL FOR MINSTER P2-45

-

- Impact noise from the press stroke

- Vibration of the press frame and surrounding structures.

- Part ejection and handling noises (e.g. dropping metal into bins).

- Air exhaust from pneumatic systems.

OCCUPATIONAL CONSIDERATIONS:

-

- Hearing protection programs may still be required (earplugs, earmuffs).

- Regular noise level monitoring (e.g., using dosimeters or sound level meters).

- Compliance with OSHA or local workplace safety regulations is a must.